Quality Control in Industrial Manufacturing

Nanosurf provides a range of systems designed for industrial quality control applications. Whether you need standard tools for 200 mm or 300 mm diameter samples or customized solutions tailored to your specific measurement and sample requirements, Nanosurf has a diverse selection of options available to cover even the largest samples.

Speak to an AFM Expert

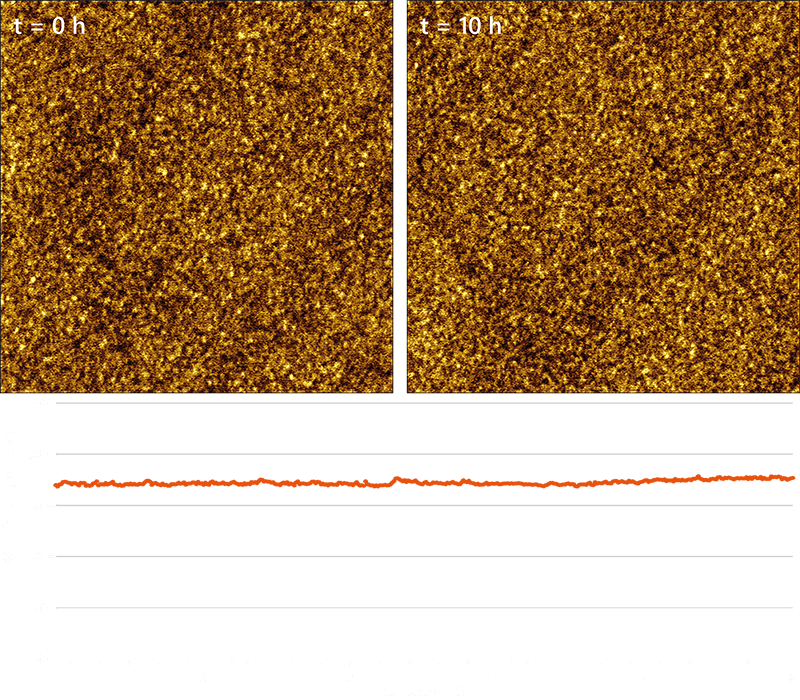

Surface Quality Control

The surface quality of a component, whether utilized in industrial manufacturing or as a final product, can profoundly influence the component’s performance and, by extension, the quality of the final product. This principle is universally applicable across a broad spectrum of industries, ranging from commonplace consumer goods such as ballpoint pens to sophisticated sectors like advanced manufacturing and semiconductors. In many instances, surface quality is directly associated with specific surface morphology attributes. Atomic Force Microscopy (AFM), with its capacity to analyze surface morphology at a resolution that significantly surpasses the diffraction limit, thereby overcoming the constraints of optical methods, in the angstrom range, emerges as an ideal instrument for such tasks. Nanosurf’s solutions for industrial quality control applications distinguish themselves by integrating the AFM with a stage explicitly engineered for a certain samples. This integration facilitates the inspection of intact workpieces straight from the production lines, obviating the need to reduce them to smaller samples typically necessitated in most AFM systems.

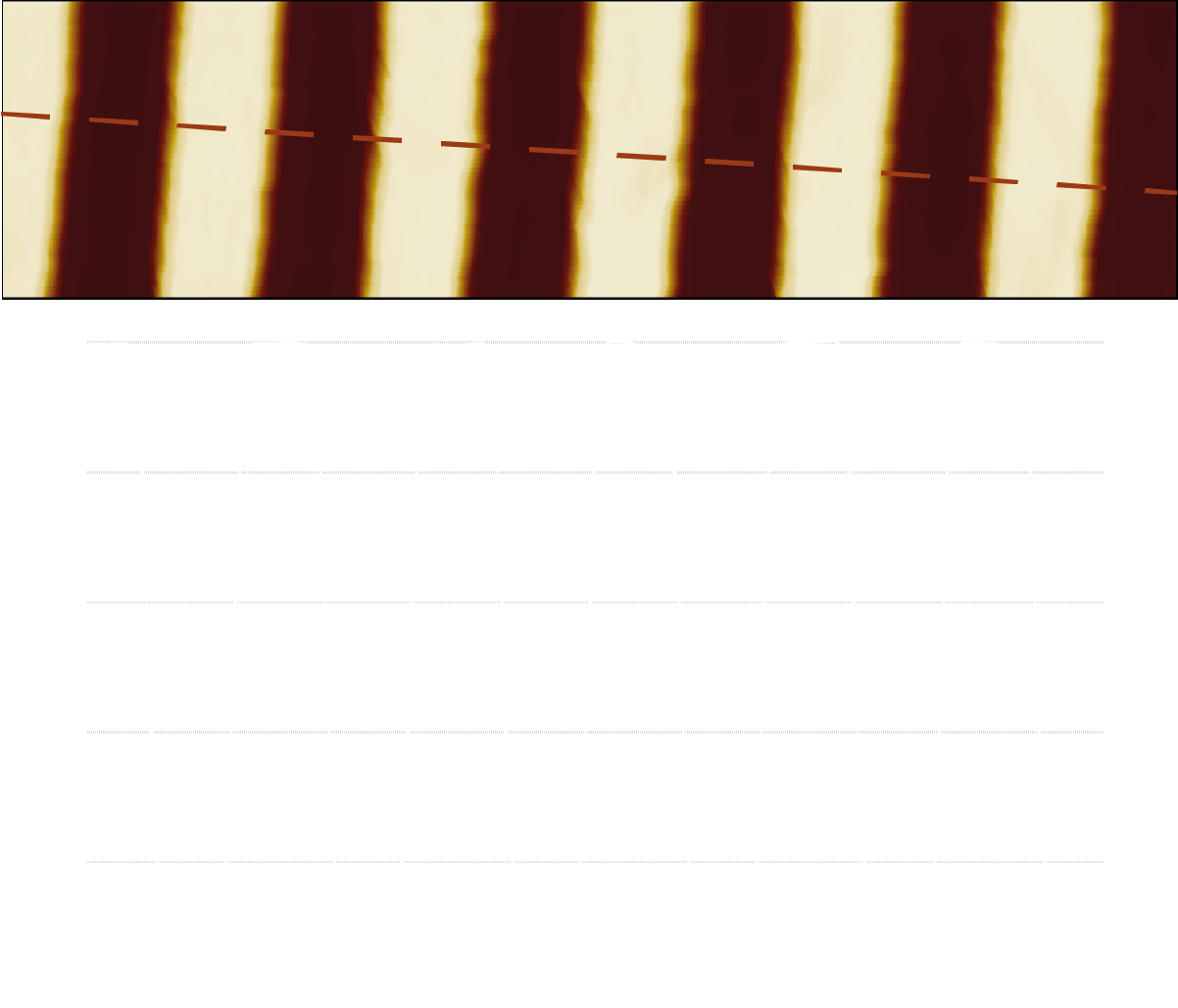

Process Development and Control

Industrial manufacturing is heavily dependent on processes that are both reproducible and well-understood, particularly as the structures being produced continue to decrease in size. The development and control of these processes necessitate a thorough analysis of the resulting workpiece, whether it’s the surface roughness, critical feature dimensions, mechanical properties, or electrical properties. AFM has evolved into an essential instrument for accurately characterizing these parameters at the nanometer scale locally, thereby facilitating an understanding of how process parameters impact the process outcome.

Automation

Operating an AFM has traditionally been a task reserved for expert users. However, in an industrial context, the operation of an AFM should be as straightforward and reproducible as possible, enabling non-expert operators to yield valid and meaningful results. Nanosurf’s Automation service offers customized automation solutions that align with the customer’s specific level of integration requirements, thereby facilitating the seamless incorporation of AFM into quality control and manufacturing processes.

Measurement Examples

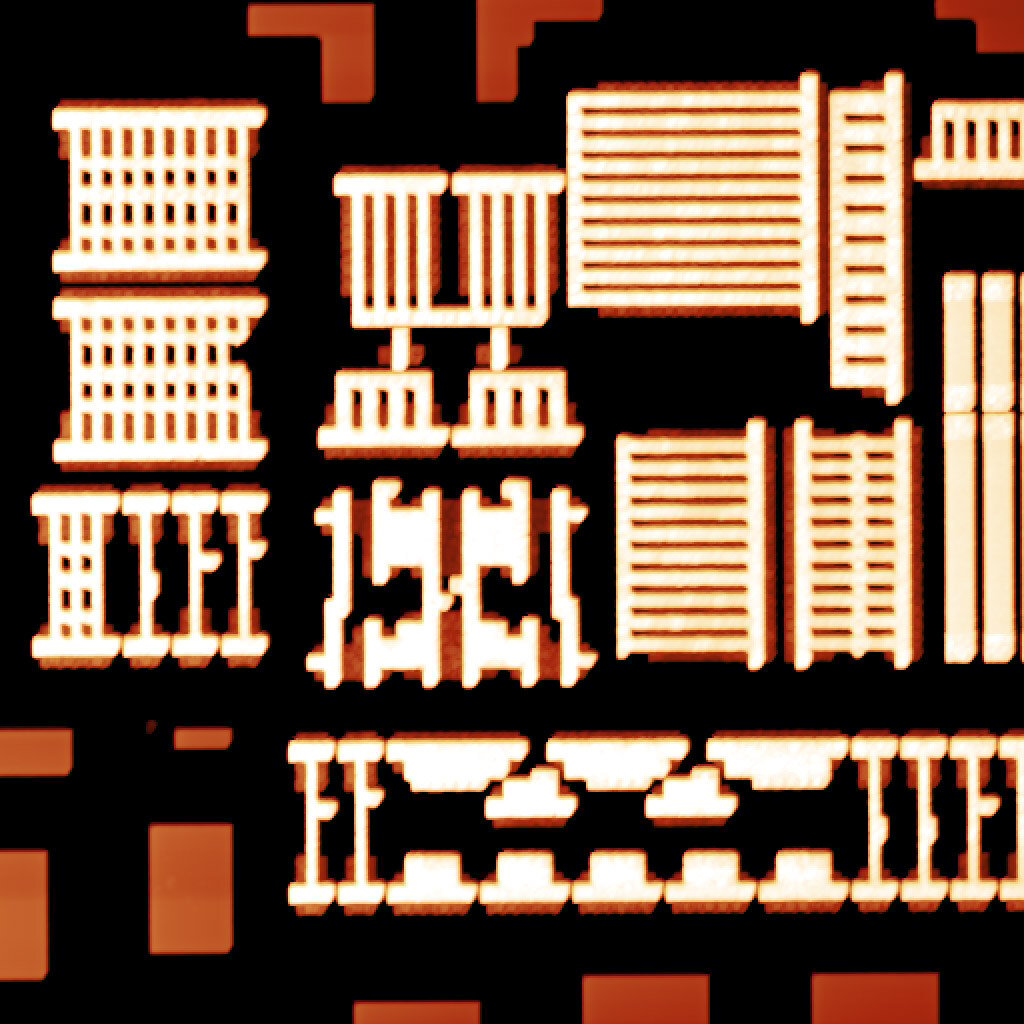

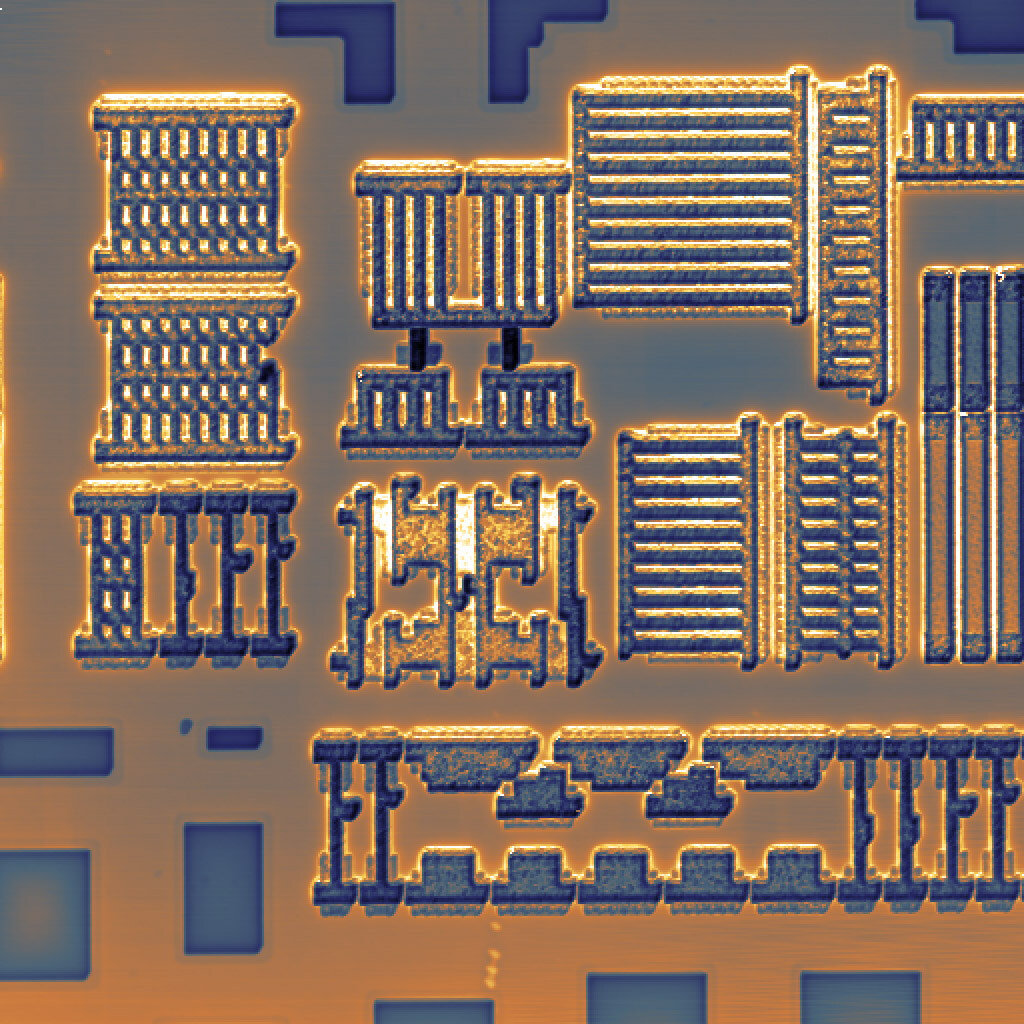

Topography of reverse-engineered silicon chip structure

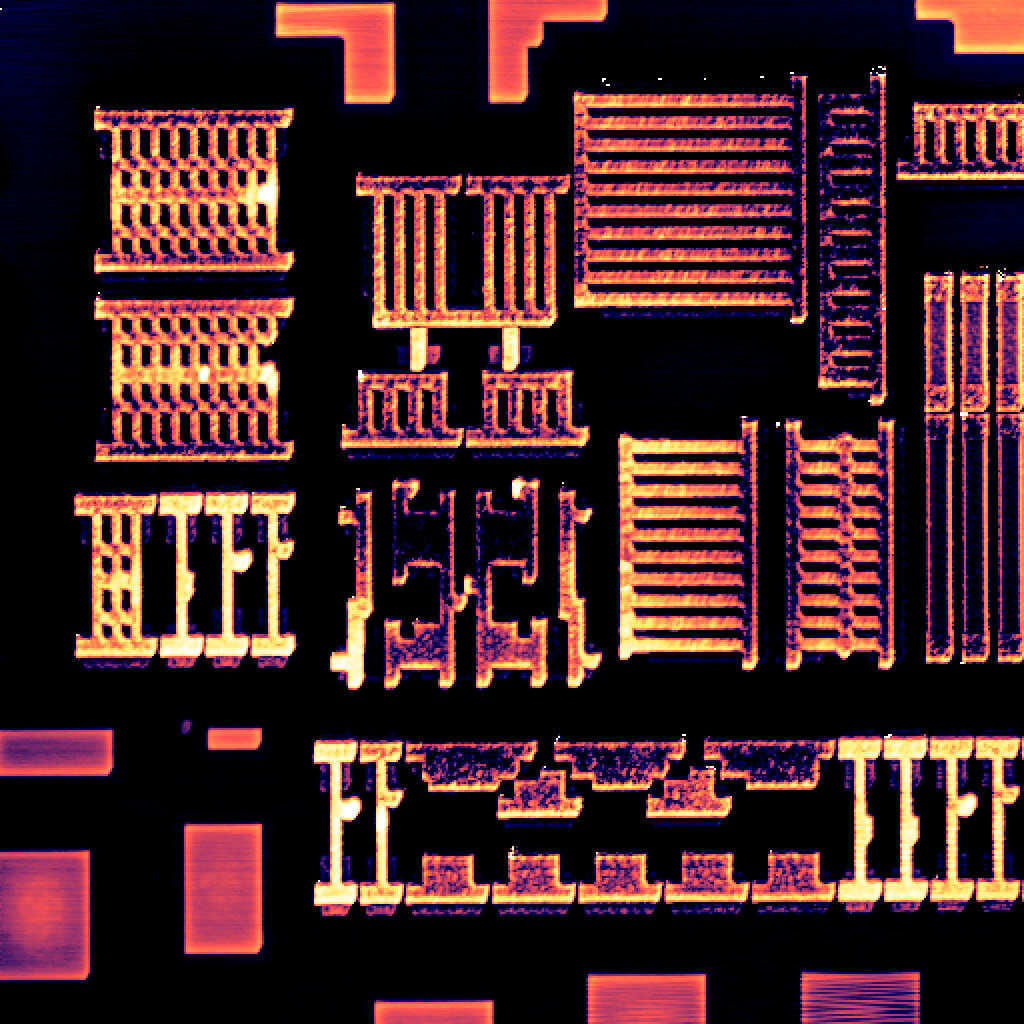

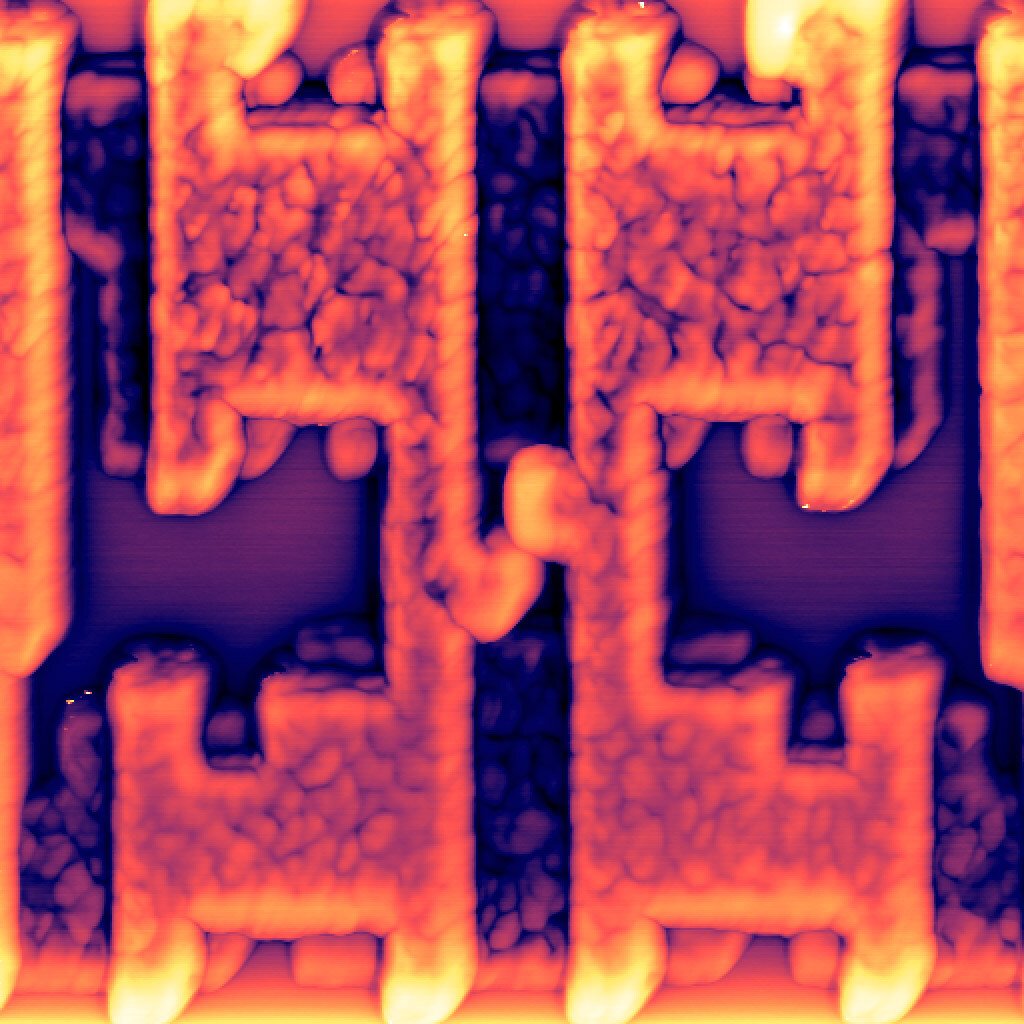

Real part of S11 parameter of reverse-engineered silicon chip structure

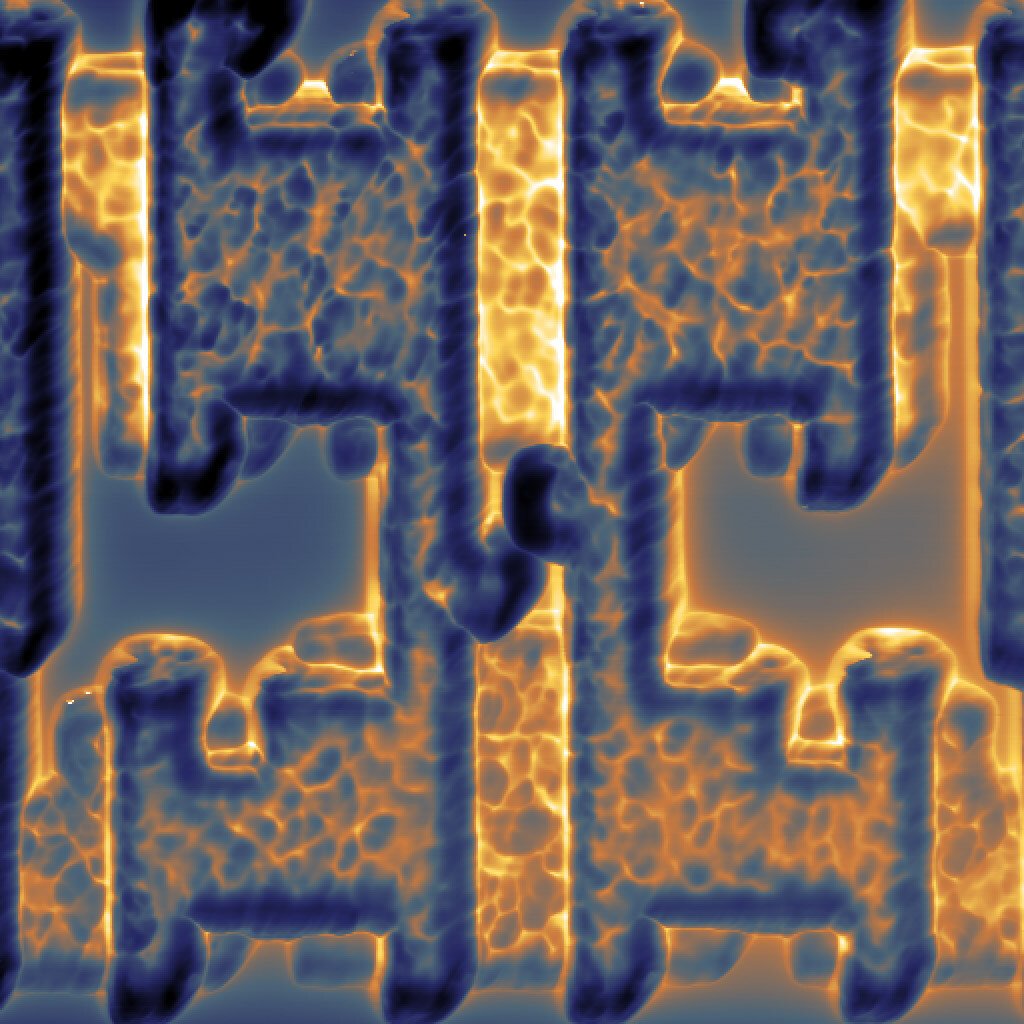

Imaginary part of S11 parameter of reverse-engineered silicon chip structure

Topography of reverse-engineered silicon chip structure

Real part of S11 parameter of reverse-engineered silicon chip structure

Imaginary part of S11 parameter of reverse-engineered silicon chip structure

Recources

Technical Note

WaveMode NMA: High-Speed Nanomechanical Mapping

This technical note gives a detailed overview of Nanosurf's WaveMode NMA technology for nanomechanical chara...

READ MOREApplication Note

Unveiling the Power of Electrical AFM Modes

Discover the advanced applications of electrical Atomic Force Microscopy in this white paper. Learn about el...

READ MOREApplication Note

Measuring the Flattest Surfaces in the Universe: Roughness Measurements with AFM

Surface roughness plays a significant role in many mechanical properties such as friction and adhesion, in s...

READ MOREInsights Article

Delivering Advanced Cleanroom-Compliant, Automated AFM Solutions for the Semiconductor Industry

Nanosurf, a leading provider of cutting-edge atomic force microscope (AFM) measurement equipment, offers ful...

READ MORERecommended AFM System

Industrial Solutions

While traditional tools for wafer analysis are essential for assessing wafer roughness and critical dimensions or performing failure analysis, the semiconductor industry's supply chain often requires different solutions. Our team of skilled engineers understands this demand and is ready to support you with tailored characterization tools. We provide a range of automation and engineering services that go beyond standard system control and sample formats. Reach out to our Industrial Solutions team to discuss your specific measurement and analysis needs.

Alphacen 300

The Alphacen 300 system is a unique AFM solution that can handle large and heavy samples with ease. It features the Flex-Mount scan head, which has a tip-scanner design that enables high-performance imaging regardless of the sample size or weight. The CX controller, Nanosurf's most advanced AFM controller, offers fast and precise control over the scan process. The dedicated acoustic enclosure reduces external noise and vibrations. Moreover, the system can be further customized with additional translation or rotation axes to suit your specific sample.

Alphacen 200 Drive

Leveraging our proficiency in crafting industrial metrology systems, Nanosurf has introduced the Alphacen 200 Drive, a sophisticated AFM system tailored to satisfy the stringent requirements of the semiconductor industry. From conducting low-noise roughness analysis via WaveMode to executing intricate electrical characterization tasks, the Alphacen 200 Drive addresses the common challenges encountered in semiconductor industry.