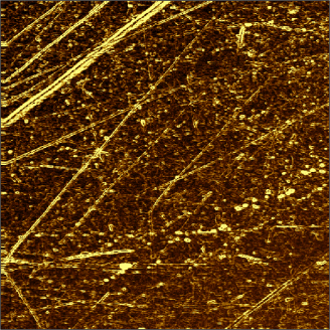

Discover the capabilities of WaveMode AFM in characterizing bottlebrush polymers with unprecedented detail and speed, ...

The ultimate tool for nanoscale research from biological molecules to advanced new materials.

The versatile mid-range research AFM that grows with your demands in modes and accessories.

A compact affordable research AFM that is astoundingly easy to use, with more than 30 modes and options.

Fastest reliable sub-Angstrom surface roughness metrology.

Bringing the power of DriveAFM to a wafer metrology system purpose-built for the requirements of the semiconductor industry.

Measure roughness and other material properties of heavy and large samples up to 300 mm and 45 kg.

For unique requirements, we will design a bespoke AFM solution, leveraging our decades of engineering expertise.

Slide an AFM onto your upright optical microscope turret for a leap in resolution.

One of the smallest ever AFMs, created for integration into custom stages or existing setups.

A flexibly mountable research-grade scan head for integration into custom stages or existing set ups.

What is atomic force microscopy (AFM)? How does AFM work? What AFM modes do I really need? How do I get started with AFM?

Learn how AFM works with cantilever/tip assembly interacting with the sample. Explore CleanDrive technology, calibration methods, and feedback principles for precise nanoscale imaging.

An overview of common AFM modes. To learn about each mode in more detail and see application, view the full article.

We regularly publish detailed reviews providing practical guidance and theoretical background on various AFM applications.

Read detailed technical descriptions about selected AFM techniques and learn how to perform specific measurements on Nanosurf instruments.

A library of links to research papers in which Nanosurf instruments were used.

Learn AFM from our library of recorded webinars, covering different measurement techniques, modes, and areas of application.

Short video clips explaining how to perform different operations on Nanosurf instruments.

Watch a product demonstration to learn about the capabilities of our AFMs.

Short videos of our AFMs.

Browse news articles, press releases and a variety of other articles all around Nanosurf

Browse Héctor Corte-Léon's weekly experiments, for inspiration, entertainment, and to discover everyday applications of AFM.

By guest author Laura Schwan.

L. Schwan1,* and U. Bröckel1

1Institute of Micro-Process-Engineering and Particle Technology (IMiP), University of Applied Sciences Trier, Environmental Campus Birkenfeld,P.O. Box 1380, D-55761 Birkenfeld, Germany.

*Email: L.Schwan@umwelt-campus.de

Link to publication: First Approach Using Fluidic Force Microscopy (FluidFM®) to Measure Adhesion Forces between Droplets and Flat/Rough Surfaces Immersed in Water

#Done with a FLEX: The Flexible Research AFM

Our research project addresses the complex field of battery recycling and deals with the difficult task of recovering valuable metals such as cobalt, nickel and lithium from the residues of pyrometallurgical recycling processes. The Priority Programme SPP2315, funded by the German Research Foundation (DFG), focuses on the concept of Engineered Artificial Minerals (EnAM) in the slag phase of pyrometallurgical processes. These EnAM are present in the form of crystals, whose formation is thermodynamically dependent. The EnAM act as a reservoir for the critical elements in the slag and are therefore worthy recycling [1,2].

However, a major scientific challenge has been to accurately quantify the wetting properties and adhesion force between EnAM crystals or more generally, particles and binding liquid droplets. To overcome this challenge, the FlexAFM in combination with the FluidFM® (Fluidic Force Microscopy) has proven to be a highly accurate tool that provides insight into the dynamics of wetting and adhesion at the microscale. In our work, an experimental setup is described that includes the formation of binding liquid droplets and initial measurements of adhesion forces between binding liquid droplets and standard flat and rough surfaces simulated by borosilicate glass and silicon carbide abrasive paper, respectively. Liquid paraffin oil is used as the binding liquid and measurements are performed in deionised water as the suspension liquid (continuous phase). An inverted microscope and a rectangular prism are used for optical control of the droplet formation (figure 2 a). It also allows the behaviour of the droplet to be studied during the measurement (figure 2 b and c).

Figure 2: a) Schematic representation of the experimental setup, FluidFM® Cantilever with droplet seen through prism and inverted microscope during adhesion force measurement b) on a flat surface and c) on a rough surface.

The pressure control system of the FluidFM® technology is used to generate the paraffin oil droplet on the cantilever tip (Ødroplet ≈ 40 µm). After droplet formation, force distance curves are generated and the size of the droplet is checked after each measurement with the help of the optical setup. The results of these adhesion force measurements are discussed in detail in [5].

This work establishes a methodology for the future evaluation of the wetting properties of EnAM crystals in relation to the selective wet agglomeration process. The versatility of the FluidFM® system also allows the study of changes in parameters such as the pH of the continuous phase and the influence of surfactants on the adhesion forces. This offers the possibility of a deeper understanding of interparticular interactions and description of wetting characteristics, paving the way for potential applications in a wide range of fields.

References:

[1] Elwert, T.; Strauss, K.; Schirmer, T.; Goldmann, D. Phase composition of high lithium slags from the recycling of lithium ion batteries. World Metall. -Erzmetall 2012, 65, 163–171.

[2] Velázquez-Martínez, O.; Valio, J.; Santasalo-Aarnio, A.; Reuter, M.; Serna-Guerrero, R. A Critical Review of Lithium-Ion Battery Recycling Processes from a Circular Economy Perspective. Batteries 2019, 5, 68.

[3] Cattermole, A.E. Classification of the metallic constituents of ores 1904, 76359.

[4] Schreier J.; Bröckel U. Multidimensional separation due to selective spherical agglomeration-Evidence of shape separation via X-ray microtomography. Particuology 2021, 58, 316-323. https://doi.org/10.1016/j.partic.2021.04.003

[5] Schwan, L.; Bröckel U. First Approach Using Fluidic Force Microscopy (FluidFM®) to Measure Adhesion Forces between Droplets and Flat/Rough Surfaces Immersed in Water. Processes 2024, 12, 99. https://doi.org/10.3390/pr12010099 .

To read more:

Determining mass of individual micron-sized particles using PicoBalance and FluidFM® probes

28.10.2025

Discover the capabilities of WaveMode AFM in characterizing bottlebrush polymers with unprecedented detail and speed, ...

27.10.2025

Read this blog and discover advanced alloy engineering and cutting-edge AFM techniques for high-resolution, ...

14.10.2025

Discover how WaveMode technology resolves the tobacco mosaic virus structure under physiological conditions with ...

18.04.2024

FridayAFM: See how one of our Industrial AFMs can be used to look at the surface of mobile phones.

28.03.2024

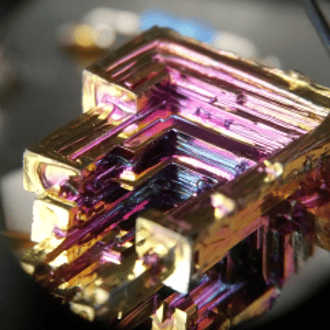

Explore the world of AFM experiments with bismuth oxide layers in this blog post. Learn about electrical measurements ...

21.03.2024

FridayAFM: Point contact diode on lead sulfide.

Interested in learning more? If you have any questions, please reach out to us, and speak to an AFM expert.